Our Capabilities

We value and foster the unique blend of energy and experience that our team of engineers and draftsmen contribute. Their combined strengths form the backbone of our renowned engineering proficiency. Whether it's detailed design, thermal calculations, FEA analysis, or more complex engineering needs, our in-house team is fully equipped to deliver comprehensive solutions that align with international codes and global quality standards.

Code & Standards

- ASME(All Codes)

- TEMA

- IBR

Software

- Thermal Design

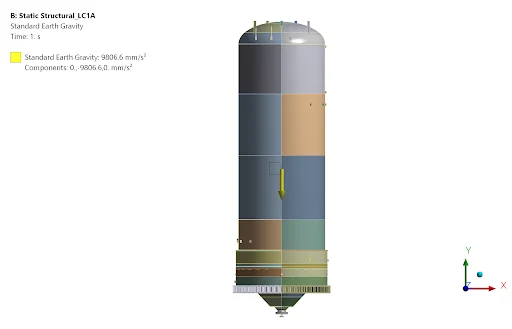

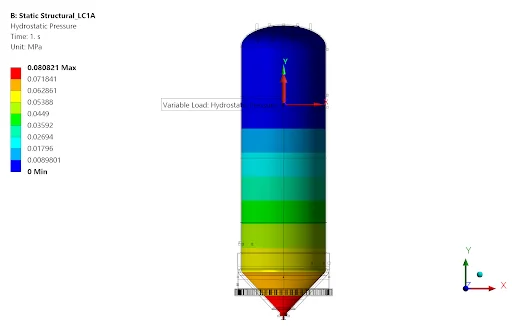

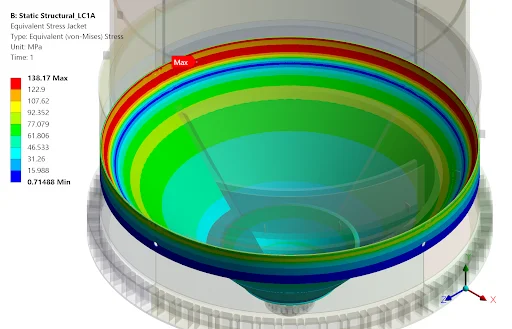

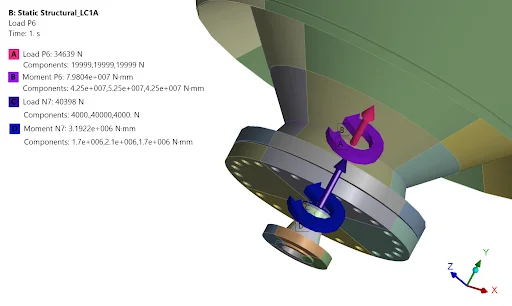

HTRI - FEA & Fatigue Analysis

ANSYS, NozzlePRO - Mechanical Design

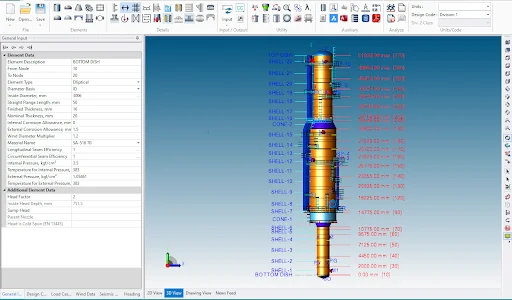

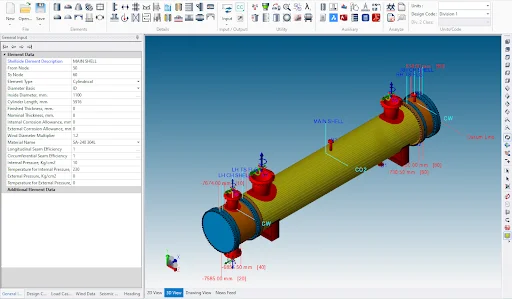

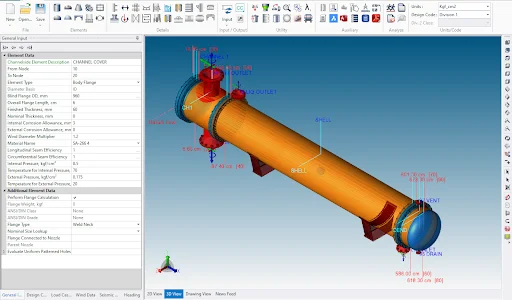

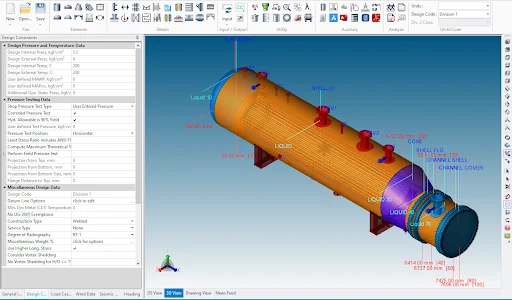

PVElite - 3-D Modeling

PDS (Inventor); 3D PV 24 - Drafting

AutoCAD

Our manufacturing facility in Umbergaon Gujurat , India is spread across an area of 68000sq. mtrs. We build critical and over- dimensional equipment with an expertise in handling exotic metallurgies underscores our leadership in innovation and quality.

"The ingeniously designed unit is capable of manufacturing equipment ranging from 20 MT to 800 MT with equal ease. However, we are not limited to this capacity—our capabilities extend beyond 800 MT as well, based on client requirements."

6.5M

Diameter

100M

Length

300T

Single shipment weight

Machinery

- Drilling

- Lathing

- Milling

- Sawing

- Cutting

- Bevelling

- Rolling

- Press Forming

- Weld Overlay

- Saw Welding Machine

With decades of fabrication experience, we have honed our expertise in welding, mastering the core processes with precision. Our capabilities include welding procedures, along with proficiency in diverse materials and welding techniques.

What sets us apart is our commitment to automation in welding, enhancing efficiency while maintaining the highest quality standards, giving us a strong competitive advantage.

Welding Processes

- Automatic Orbital Welding for Tube to Tubesheet joints

- Submerged arc welding (SAW)

- Gas tungsten arc welding (GTAW)

- Shielded metal arc welding (SMAW)

Welding Processes

- Gas metal arc welding (GMAW)

- Narrow gap welding

- Flux cored arc welding (FCAW)

Metallurgies

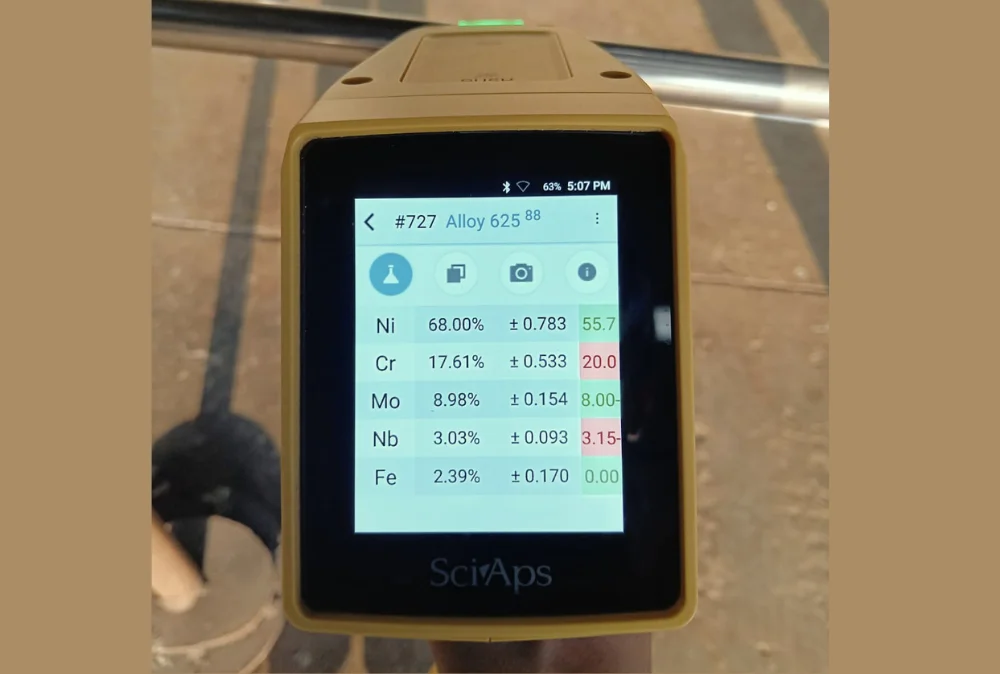

Beside the high pressure Equipment's market, Gemini developed extensive knowledge and skills handling a very wide range of materials. Today the Company can treat all the main materials in charge of the Pressure Equipment's manufacturing.

- Carbon Steel(LTS, NACE, HIC)

- LAS (P4, P5A, P5B)

- Low Alloy

- High Alloy Steels 5% Cr

- Stainless Steel (Austenitic, Ferritic, Martensitic)

- Duplex, Super Duplex, Lean Duplex

- Inconel (625, 825)

- Monel

- Incolloy (800, 800H, 832)

- Hastealloy (C22, C276, C2000)

- Pure Ni (Ni-200)

- Brass

- Cupronickel

- Titanium (Grade 1, 2, 7, 12)

Quality is the foundation of our business approach. Every piece of equipment produced in our facility is crafted to meet the highest industry standards. Our commitment to excellence has earned the trust of our clients, fostering long-term relationships and encouraging repeat business.

In- house NDT facility for PMI, PT, UT, RT, TOFD (Time of Flight Diffraction) and Helium Leak Test.

QA/QC Certifications

ISO 9001:2015 - (QMS)

ISO 14001:2015 - (EMS)

OHSAS 45001:2018

NB - Boiler & Pressure Vessel Inspection

U - ASME U Stamp

U2 - ASME U2 Stamp

R - ASME R Stamp

S - ASME S Stamp

Strategically located just 180 kilometers from Mumbai JNPT Port and well-connected by road, rail, and sea through the upcoming Nargol Port in Valsad near umbergaon plant, our facility ensures seamless logistics for global and domestic clients."